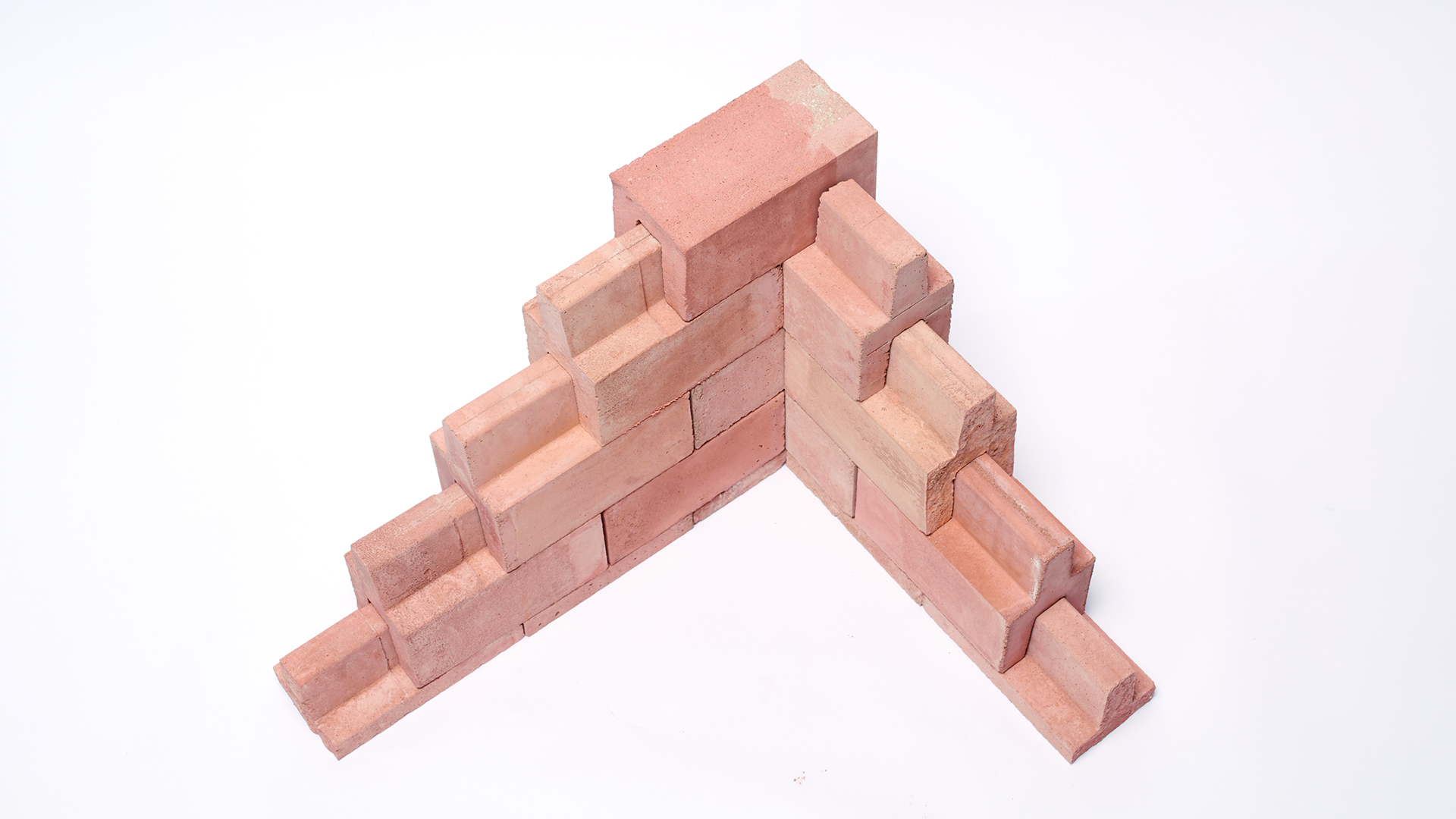

»A clever design where the finesse is in the details. Masonry construction tasks can be accomplished with flexibility using only a few different bricks, which are made from construction waste and recycled brick dust. Intelligent stacking and interlocking replaces mortar, which also facilitates eventual deconstruction.«

Prof. Matthias Held

Three questions for Maren Klamser

How did the idea for 5 TONS come about?

In the course of my studies, I became more and more interested in the fields of sustainable and circular design. It didn’t take long for me to come across the issues faced by the construction industry with regard to environmental pollution and the scarcity of raw materials. I decided to take a creative and impartial look at the implementation of the concept of sustainability in the construction industry, which was ultimately the starting point for the 5 TONS project.

What was your personal highlight in the development process for 5 TONS? Was there a low point?

The biggest challenge was in finding a way of reusing mineral construction waste. I dealt intensively with historical building materials and developed a theoretical approach to returning building rubble and broken masonry to the material cycle. The highlight of the development process was definitely when the theoretical material concept also worked in practice.

Where do you see your project in five years?

The project has passed the status of proof-of-concept. The compressive strength has been tested and the recyclability has been demonstrated, but the potential of the material is yet to be fully explored. In the future, I would like to continue the material research, test out the full closure of the material cycle and develop a concept together with material experts to realise the further potential of the material and define different quality categories.